Introduction of Laser Shielding Plate

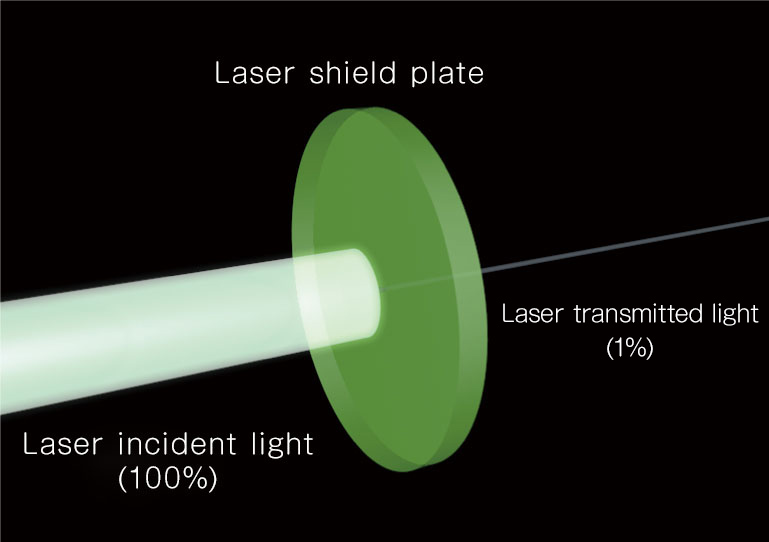

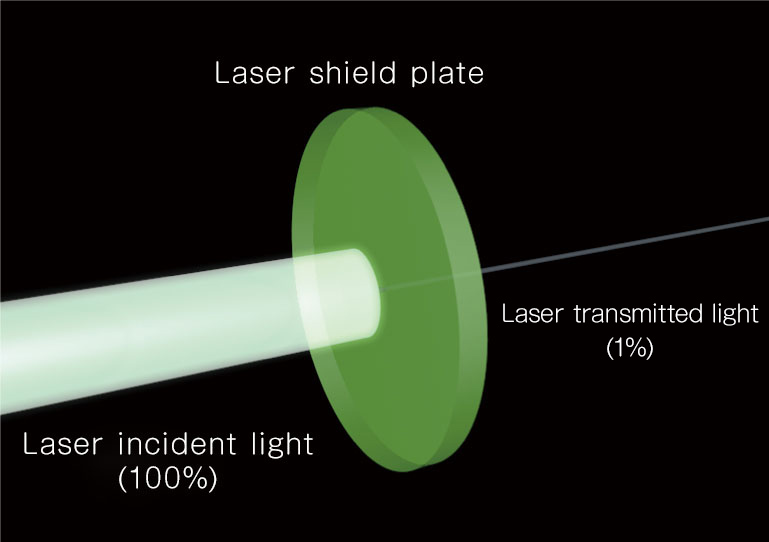

Our laser shield plate has shielding (laser shielding) performance of optical density*4-6 against

various laser wavelengths, and is useful for safety measures for workers. Compared to commonly used

PMMA (acrylic resin), our laser shield plate is designed to maximize the high flame resistance,

chemical resistance, alcohol resistance, and impact resistance of PVC (polyvinyl chloride resin),

which is the base material.

*Optical density is the logarithm of the degree of absorption, and its relationship to transmittance

is shown in the table below.

| Optical Density |

Attenuation ratio |

Transmittance(%) |

| 0 |

0 |

100 |

| 1 |

1/10 |

10 |

| 2 |

1/100 |

1 |

| 3 |

1/1000 |

0.1 |

| 4 |

1/10000 |

0.01 |

| 5 |

1/100000 |

0.001 |

| 6 |

1/1000000 |

0.0001 |

Transmittance:1%→Attenuation ratio:1/100→OD Value:2

Typical industrial equipment using laser technology

- Measuring equipment

- Information processing equipment such as DVD and Blu-ray players

- Bar code readers

- Medical equipment

- Cutting, drilling, welding, and other processing equipment

- Marking equipment

- Surface modification and treatment equipment

etc.

Observation window of processing equipment

Typical applications of our laser shield plate

- Safety covers for laser markers and processing equipment using laser beams

- Observation windows for laser processing machines

- Safety measures and protective partitions around laser processing equipment

partitions